Parking Lot Installation: Key Considerations for Successful Projects

Effective planning and design are critical for a successful parking lot installation.

Creating a well-designed parking lot is vital for any business or property. The installation process involves various essential steps that ensure safety, accessibility, and functionality. From the initial planning stages to the final striping, each phase plays a crucial role in transforming a simple plot of land into an organized space that welcomes customers and employees alike.

At Trueline Striping, your project’s success begins with expert planning and careful execution. Our team specializes in new construction striping, ensuring that your parking lot not only looks professional but also adheres to ADA compliance standards. By using high-quality materials and advanced techniques, we guarantee durable markings that enhance traffic flow and overall safety.

Whether you’re establishing a new parking lot or revitalizing an existing one, you can rely on Trueline Striping to deliver the best results. With services offered across various locations including Waco, Temple, Belton, and Killeen, we are dedicated to providing you with a seamless experience that prioritizes your needs and satisfaction.

Planning and Parking Lot Design

Effective planning and design are critical for a successful parking lot installation. Focusing on site assessment, layout, and compliance with local regulations ensures optimal functionality while enhancing your property's value.

Site Assessment and Planning

Begin with a thorough site assessment to determine the best location for your parking lot. Evaluate factors like soil stability, existing structures, and drainage to inform your design. Traffic patterns in the area will affect how vehicles enter and exit, so understanding this flow is essential.

Consider the size and type of vehicles using the facility. For commercial properties, accommodating larger vehicles may be necessary. This planning stage is also an opportunity to assess any landscape features that could enhance aesthetics while maintaining functionality.

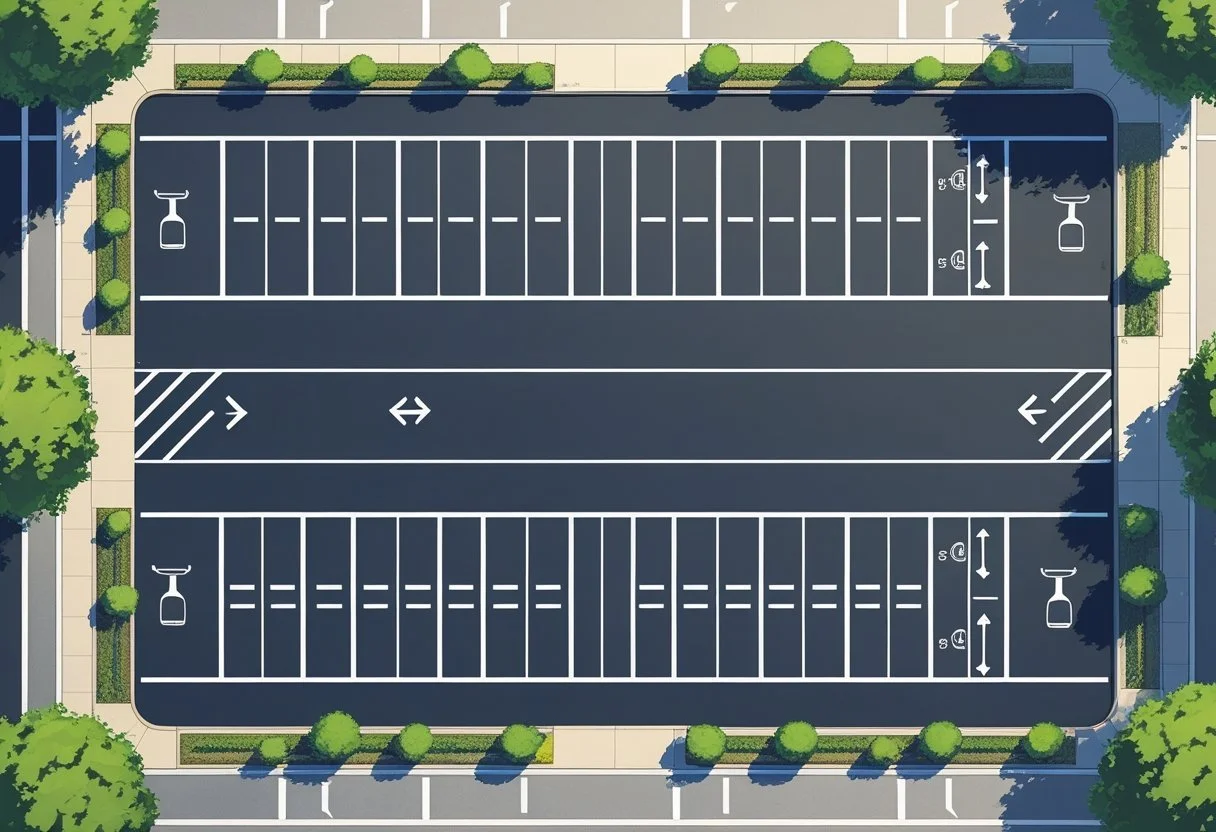

Parking Lot Layout and Traffic Flow

A well-thought-out layout is crucial for optimizing traffic flow and circulation within the parking lot. Implement features such as one-way lanes, clearly designated parking spaces, and adequate maneuvering room to reduce congestion.

For efficiency, aim for a balance between the number of spaces and the ease of access. Clearly marked paths ensure that both pedestrians and vehicles can navigate safely. Implementing smart design can lead to fewer accidents and increased customer satisfaction.

Permits and Regulations

Before proceeding with construction, ensure you acquire all necessary permits. Local regulations may dictate specific requirements for paving materials, drainage systems, and accessibility guidelines.

Navigation of these regulations can often be complex, so consider consulting professional services for guidance. Non-compliance can lead to significant setbacks or fines, impacting your project's timeline and budget. Adhering to these regulations not only ensures legal compliance but can also enhance property value through improved safety features.

Trueline Striping is equipped to assist with your parking lot striping needs, emphasizing clear markings for both safety and efficiency.

Site Preparation and Grading

Effective site preparation and grading play critical roles in achieving a durable and functional parking lot. This process ensures proper drainage, supports the subgrade layer, and establishes a stable foundation for the pavement. A meticulous approach to these tasks can prevent future issues and extend the life of your parking lot.

Demolition and Clearing

Before commencing the grading process, you need to clear the site of any existing structures or debris. This involves demolition of old pavement, removal of vegetation, and disposal of waste. Ensuring that the area is free of obstacles allows for accurate grading and the establishment of necessary drainage features.

Take care to assess the site thoroughly. Identify any underground utilities before beginning demolition. Mark these utilities to avoid costly damages during excavation. A clean site lays the groundwork for effective grading and prevents complications later in the project.

Underground Utilities and Drainage Solutions

Addressing underground utilities is crucial before grading. Utilities can include water pipes, electricity, gas lines, and sewage systems that should be accurately mapped to prevent interference during construction. It’s advisable to consult local utility companies to obtain blueprints or conduct a utility survey.

Additionally, effective drainage solutions are essential for managing water runoff. Installing proper drainage systems, such as drainage slopes, helps direct water away from the parking lot, alleviating potential flooding or erosion issues. Incorporating features like crushed stone in your drainage design can effectively manage water while supporting the base layer.

Grading, Sloping, and Base Layers

Grading is the process of leveling and shaping the ground to create a solid subgrade layer. This action involves excavating high spots and filling low areas to achieve a uniform surface. The slope is crucial, as it helps facilitate water drainage and prevent standing water in your lot.

After grading, establishing the base layer is vital for durability. Common materials include stabilized gravel or crushed stone, which provide support for the pavement above. Conducting a proof roll can help identify weak spots in your base layer before finalizing your surface material. This ensures your parking lot has a strong foundation, promoting longevity and performance.

For reliable parking lot striping services, consider partnering with Trueline Striping, serving locations like Waco and Temple.

Parking Lot Installation Process

The parking lot installation process involves several critical steps that ensure the longevity and functionality of the finished product. Key aspects include constructing a strong base layer, utilizing effective asphalt paving techniques, and ensuring proper compaction.

Base Layer Construction

The base layer is essential for a durable parking lot. It typically consists of crushed stone or gravel, which provides stability and support for the asphalt layer above. You should aim for a base thickness of at least 6 to 8 inches, depending on the soil type and expected traffic load.

To begin, clear the site of any vegetation and debris. Then, analyze drainage to prevent water accumulation. Proper grading ensures water drains away from the surface. After laying the base materials, compact them thoroughly using a plate compactor or roller. This first layer is crucial as it directly influences the lifespan of your asphalt.

Asphalt Paving Techniques

Asphalt paving involves multiple steps, starting with selecting the right asphalt mix. The mix typically contains aggregates, binder, and filler. When pouring asphalt, the temperature of the mixture should be between 300°F to 330°F for optimal results.

Using an asphalt paving machine allows for a smooth, even layer. The thickness of the asphalt layer usually ranges from 2 to 3 inches. Ensure that the installation is done in manageable sections to prevent the asphalt from cooling too quickly. You can collaborate with experts for precise asphalt parking lot installation that meets your specifications.

Compaction and Rollers

Compaction is vital in achieving a stable and long-lasting surface. After the asphalt is poured, it's essential to compact it while it's still hot. Use rollers to achieve a smooth finish and eliminate air pockets; this improves the asphalt's density and strength.

Different types of rollers, such as vibratory and static rollers, can be utilized based on the project size. Compaction should occur in multiple passes to ensure the asphalt is evenly settled. Proper compaction not only enhances the durability of your parking lot but also promotes effective pavement performance.

For your striping needs, consider Trueline Striping. We provide various services, including new construction striping and ADA compliance marking, ensuring your parking lot is both functional and visually appealing.

Finishing and Markings

Proper finishing and markings are crucial to ensuring that your parking lot functions efficiently. This includes curb installation, surface milling, and effective pavement marking strategies that enhance organization and safety.

Curb and Concrete Installation

Curb installation is fundamental for defining the boundaries of your parking area. Effective curbing guides vehicle movement and can help manage stormwater drainage. There are various materials for curbing, including concrete or pavers, which should be selected based on the aesthetic and functional needs of your lot.

Concrete parking lots often require a strong edge to withstand the weight of vehicles. Ensure the installation process includes proper setting and alignment. Choosing a durable concrete mix enhances longevity. Trueline Striping can assist in the installation to ensure your curbs are precisely defined and durable.

Surface Milling and Butt Joints

Surface milling is a process used to remove a portion of the existing pavement surface to create a smoother and more even finish. This technique is essential before applying new asphalt or markings.

Butt joints are the connections between different pavement sections, and they need to be executed seamlessly. Proper milling at these joints reduces the chance of water pooling and improves the visual appeal. It is important to smooth these transitions to prevent tripping hazards and ensure a professional appearance. Engaging a reliable service like Trueline Striping ensures your parking lot’s surface is correctly prepared for long-lasting performance.

Pavement Marking and Parking Space Lines

Pavement marking is vital for enhancing organization and safety in your parking lot. This includes painting clear and distinct parking space lines that guide drivers and optimize space usage.

The choice of materials for markings can significantly impact durability. High-quality paint that is resistant to wear and weather will ensure your lines remain visible. Remember to incorporate ADA compliance guidelines when marking spots reserved for disabled parking. A well-marked parking lot enhances aesthetics and functionality, making your property more inviting. Trueline Striping specializes in this aspect to ensure that your markings not only look professional but also serve their purpose effectively.

Maintenance and Longevity

Effective maintenance is crucial for ensuring the longevity of your parking lot. By prioritizing protective measures, regular upkeep, and prompt repairs, you can enhance the lifespan of your asphalt surface.

Sealcoating and Protective Measures

Sealcoating is an essential step in maintaining your asphalt parking lot. This protective layer serves as a barrier against UV rays, water, and vehicle fluids. Applying sealant every 1-3 years can prevent deterioration and cracking.

It’s important to choose high-quality sealcoating products that create a durable surface. Brands that offer premium sealants can extend the life of your parking lot significantly. Investing in this process helps maintain a polished appearance while safeguarding your asphalt from harsh elements.

Regular inspections after application can identify areas that need touch-ups or further protective treatments. Implementing sealcoating as part of your routine maintenance can save you from costly repairs down the line.

Regular Maintenance and Repairs

Regular maintenance is key to a long-lasting asphalt parking lot. Scheduling routine inspections allows you to identify wear and tear before it escalates into significant issues. Look for signs of cracking or surface flaking.

For minor cracks, simple patching can effectively restore your parking lot's integrity. Using asphalt filler products can seal these imperfections, preventing water infiltration that leads to larger problems.

Create a maintenance schedule that includes cleaning and debris removal to avoid staining and surface damage. Keeping your lot clear can also enhance safety and appearance, allowing your customers to enjoy a welcoming atmosphere.

Pothole Repair and Preventative Care

Potholes can be detrimental to your asphalt parking lot, posing both safety concerns and costly repair challenges. Promptly addressing potholes with targeted repair strategies can prevent further damage.

Utilizing a hot asphalt mix for repairs ensures longevity and durability. If left unattended, potholes can expand and cause significant structural damage, requiring more extensive repairs.

Implement preventative measures, such as proper drainage systems and regular surface inspections, to minimize pothole formation. Working with professionals at Trueline Striping allows you to maintain a well-marked and well-kept parking area, emphasizing safety and functionality.

Choosing an Experienced Contractor

Selecting the right contractor is crucial for successful parking lot installation. An experienced contractor ensures quality workmanship and adherence to specifications, resulting in a durable and efficient parking area. Key factors include reputation, relevant experience, and specific capabilities that align with your needs.

Selecting a Reputable Parking Lot Contractor

When looking for a parking lot contractor, check their reputation in the industry. Seek out contractors with proven experience in projects similar to yours. Look for reviews and testimonials from previous clients to gauge their reliability and service quality.

A solid portfolio showcasing past work can indicate their expertise in handling different types of installations. Additionally, verify their credentials and licenses to ensure compliance with local regulations. An established contractor often has better access to quality materials and skilled labor.

Consider also reaching out to previous clients for references. This step can provide insight into their working relationship, responsiveness, and problem-solving abilities during the project.

Key Considerations for Hiring

Once you’ve identified potential contractors, focus on several critical considerations. First, assess their experience specifically with parking lot paving. Inquire about their previous projects and the challenges they overcame.

Next, clear communication is essential. A good contractor should be approachable and responsive to your inquiries. Discuss your project’s timeline and ensure they can deliver on schedule. Also, evaluate their pricing structure—transparency is key.

Furthermore, inquire about warranties and post-installation support. A reliable contractor often stands behind their work and offers follow-up services. At Trueline Striping, our commitment includes exceptional quality in services like New Construction Striping and ADA Compliance, tailored to meet your specific requirements across Central Texas.

Frequently Asked Questions

Parking lot installation involves various aspects, including costs, materials, and specific requirements for different types of installations. Knowing the answers to these questions can help streamline the process and ensure compliance with regulations.

How much does it cost to install a new parking lot?

The cost for installing a new parking lot typically ranges from $2 to $7 per square foot. Factors influencing this cost include the size of the lot, selection of materials, and labor charges. You'll want to budget for additional expenses such as drainage systems and lighting.

What are the options for parking lot surfacing materials?

Common surfacing materials for parking lots include asphalt, concrete, and gravel. Asphalt offers durability and a smooth surface, while concrete provides longevity and lower maintenance. Gravel can be an economical choice, but it requires edging and regular maintenance.

What is required for residential parking lot installation?

For residential parking lot installation, you'll need to consider zoning laws and local building codes. Obtain any required permits and ensure compliance with regulations governing size, drainage, and materials. Additionally, check your homeowners' association rules if applicable.

What are the specifications for a gravel parking lot design?

A gravel parking lot design should include a solid base layer of crushed stone, typically 6-8 inches deep. You'll also need to incorporate proper drainage systems to prevent water pooling. Borders may be required to keep the gravel contained and defined.

How can one reduce the costs involved in parking lot construction?

To reduce costs in parking lot construction, consider simplifying design elements and using cost-effective materials. Comparing multiple bids from contractors can also help you find competitive pricing. Regular maintenance of the lot will prolong its life and minimize future repair costs.

What is the process for asphalt parking lot installation?

The process for asphalt parking lot installation includes site preparation, grading, and creating a solid base. Once prepared, hot asphalt is laid and compacted. Finally, markings are applied for organization and safety. Trueline Striping can assist with creating clear and durable lines for your new lot.

Parking Lot Maintenance Checklist: Essential Steps for Optimal Condition

A well-structured parking lot maintenance program is vital for ensuring safety and functionality.

Maintaining a parking lot is essential for ensuring safety, efficiency, and a positive experience for your customers and employees. A well-structured [parking lot maintenance checklist] can help you address key areas, such as surface conditions, signage, and lighting, all of which contribute to a functional space. By following a thorough checklist, you can prolong the life of your lot and avoid costly repairs down the line.

At Trueline Striping, we understand the importance of clear, durable markings that facilitate traffic flow and enhance safety. Whether you require new construction striping, restriping, or ADA compliance, our services ensure that every aspect of your parking lot aligns with industry standards. A properly maintained parking lot not only looks good but also plays a crucial role in maintaining a professional environment.

As you navigate the various elements of parking lot maintenance, remember that each detail matters. From identifying cracks to ensuring proper lighting, a comprehensive checklist keeps your parking facility in top shape. Let Trueline Striping assist you in creating a welcoming and organized space that reflects your commitment to quality and safety.

Establishing a Parking Lot Maintenance Program

A well-structured parking lot maintenance program is vital for ensuring safety and functionality. This involves routine inspections, a preventive maintenance schedule, and thorough documentation. Each aspect plays a critical role in maintaining the integrity of your parking lot.

Routine Inspections

Conducting regular inspections allows you to identify potential issues early. Utilize a parking lot inspection checklist to assess key features such as pavement condition, signage, and lighting.

Inspect for:

Potholes and cracks

Faded markings that need repainting

Lighting functionality to ensure safety

You should schedule these inspections at least quarterly. In addition to visual checks, consider using preventive maintenance software to track findings and develop an action plan. This method helps property owners and facility managers stay proactive in maintaining the parking lot’s condition.

Preventive Maintenance Scheduling

Creating a preventive maintenance schedule helps you stay organized and efficient. Prioritize tasks based on inspection findings and seasonal needs. This could include:

Sealcoating to protect asphalt

Striping services for clear markings

Engage with professionals, like those at Trueline Striping, to manage tasks such as ADA compliance striping and refresh rates. Schedule maintenance activities during off-peak hours to minimize disruption to customers. A proactive approach extends the lifespan of your lot and improves overall safety and aesthetics.

Documentation and Recordkeeping

Effective documentation is crucial for tracking the history of maintenance activities and expenditures. Maintain records of inspections, repairs, and maintenance schedules in a central location.

Key records to keep include:

Inspection reports

Maintenance logs

Photographs of issues and repairs

This practice not only helps in planning future maintenance but also aids in compliance with local regulations. By keeping detailed records, property owners and facility managers can justify expenditures and improve decision-making for long-term parking lot management.

Parking Lot Surface Assessment

Regular assessment of your parking lot's surface is crucial for maintaining safety and functionality. By focusing on surface condition, identifying damages, and understanding oxidation effects, you can ensure a well-maintained lot that enhances user experience.

Surface Condition Evaluation

Assessing the surface condition involves examining both asphalt and concrete for wear and tear. Look for signs of surface deterioration, such as raveling, fading, or pooling water. Use a systematic approach to check for unevenness and surface integrity. A level surface is key to preventing accidents.

Consider creating a checklist for your evaluation:

Inspect for level areas.

Note any fading markings.

Check for drainage issues.

Addressing these concerns early can prevent costly repairs down the line. Regular evaluations help maintain the parking lot's aesthetic and functionality.

Identifying Cracks and Potholes

Regular inspection for cracks and potholes is vital for parking lot maintenance. Start by walking the lot to spot cracked paving and any visible depressions. Cracks often indicate underlying issues, while potholes pose immediate safety risks.

Document the size and location of each imperfection. Smaller cracks can often be filled, preventing further damage, while larger potholes may require significant asphalt repair. Consider that prompt repairs can save money and enhance safety.

Keep an eye on high-traffic areas where wear is most likely. This proactive approach can extend the life of your pavement and reduce risks for vehicles and pedestrians.

Oxidation Process Effects

Oxidation affects the performance and appearance of your parking lot. For asphalt, exposure to UV radiation and oxygen leads to hardening and brittleness. This process diminishes flexibility, making the surface more susceptible to cracks and damage.

To combat oxidation, consider applying sealcoating every few years. This protective layer can help maintain flexibility and color while extending the life of the asphalt. Regular assessments should include checking for oxidation signs to inform your maintenance strategy.

By understanding these factors, you can implement effective measures to keep your parking lot in optimal condition. Trueline Striping offers comprehensive solutions to help you address these concerns efficiently.

Critical Maintenance Tasks

Regular maintenance is essential for ensuring the safety and functionality of your parking lot. This includes addressing cracks and potholes, applying sealcoating, maintaining cleanliness, and keeping markings visible and clear. Below are critical maintenance tasks to focus on.

Crack Sealing and Pothole Repair

Cracks in your asphalt can quickly lead to larger problems, making crack sealing a priority. This process involves cleaning out debris and filling cracks with a specialized sealant that prevents moisture intrusion. By sealing such openings, you extend the lifespan of your lot and reduce repair costs over time.

Pothole repair is equally important. Potholes not only pose safety risks but also decrease the overall aesthetic of your parking area. The typical repair method includes removing loose asphalt, applying a hot mix asphalt patch, and compacting it to create a smooth surface. Both tasks should be performed regularly and before winter weather sets in to prevent further damage.

Sealcoating and Sealcoat Application

Sealcoating protects the asphalt surface from damage caused by UV rays, water, and oil spills. A well-timed application can significantly extend the life of your parking lot. The ideal frequency is every 2-3 years, depending on traffic levels and wear.

Before applying sealcoat, ensure the surface is clean and free of debris. This typically involves a thorough sweeping and washing to eliminate dirt and oil stains. A professional application results in a smooth, even finish that enhances the appearance of your lot while safeguarding against weather-induced damage.

Parking Lot Cleaning and Debris Removal

Regular parking lot cleaning is crucial for maintaining aesthetics and safety. Accumulated debris, such as leaves, litter, and spilled substances, can create hazards or detract from the visual appeal of your property. Implementing a schedule for sweeping and pressure washing every few weeks is recommended for optimal results.

In addition to routine cleaning, consider the use of specialized equipment for larger areas. This ensures a thorough debris removal process that minimizes the risk of slips and falls. A clean parking area reflects professionalism and encourages customer satisfaction.

Line Striping and Restriping

Clear and visible markings are essential for guiding traffic flow and ensuring safety. Over time, the paint used for line striping can fade, making restriping necessary. This process involves removing old lines, if needed, and freshly painting the essential markings to meet safety standards.

Consider hiring experts like Trueline Striping for your line striping needs in locations such as Waco and Killeen. They specialize in new construction striping and ADA compliance, ensuring that your parking lot meets both safety and accessibility requirements. Regular restriping not only improves safety but also creates an inviting atmosphere for your customers.

Safety, Accessibility, and Regulatory Compliance

Maintaining a parking lot involves ensuring safety, accessibility, and regulatory compliance. Each aspect contributes to a smooth and secure experience for both customers and employees. The following sections detail critical components necessary for achieving these goals.

Signage and Traffic Markings

Proper signage and traffic markings are vital for guiding drivers and pedestrians. Clear parking lot markings delineate parking lanes, pedestrian crosswalks, and traffic directions, helping to manage vehicle flow and prevent accidents.

You should regularly inspect and maintain signage to ensure it meets visibility standards. Signage must be placed in strategic locations, such as near entrances and exits, to communicate important information effectively. Use reflective materials for nighttime visibility.

Consider the use of curb warnings as additional safety measures. These tactile indicators alert drivers to changes in direction or potential hazards around the parking area. Effective parking lot striping reinforces safety, ensuring everyone understands their designated spaces.

Lighting and Visibility

Adequate lighting is essential for enhancing visibility and safety in your parking lot. Poorly lit areas can lead to accidents and security issues, posing risks to both drivers and pedestrians.

Incorporate motion-activated lights and evenly distribute fixtures across high-traffic areas. Aim for illumination levels that exceed local regulations while ensuring dark spots are eliminated.

Consider installing security cameras as part of your lighting plan to deter crime and enhance safety. Proper sight lines should be maintained by avoiding obstructions like landscaping or signage. When planning your lighting, keep in mind emergency access routes to ensure safe navigation in case of an incident.

ADA Regulations and Accessible Routes

Compliance with ADA regulations is crucial for making your parking lot accessible. This includes providing designated accessible parking spaces and clear pathways that guide individuals with disabilities safely.

These spaces must be strategically located near building entrances and marked appropriately with van-accessible designations when necessary. Ensure the accessibility route is free from obstacles, such as curbs or landscaping.

Regular inspections can help identify areas needing improvement, such as faded markings or inadequate signage. Employing a professional service like Trueline Striping will enhance your parking lot's ADA compliance, ensuring that all users can navigate your space comfortably.

Structural Features and Infrastructure Management

Effective management of parking lot structural features is crucial for safety, efficiency, and traffic flow. Key components include entrances, drainage systems, and safety barriers. Each aspect requires regular inspection and maintenance to ensure compliance and functionality.

Entrances, Exits, and Gates

Controlling traffic flow starts at entrances and exits. Clear markings and signage guide vehicles safely into and out of your lot. Ensure gates are functioning correctly, preventing unauthorized access while allowing smooth traffic.

Regular inspections of gate closure safety features are vital. Check mechanisms for proper operation and wear. If damaged, repair or replace components immediately to avoid accidents. Well-maintained entrances and exits optimize user experience and enhance overall safety.

Drainage Systems and Water Management

A crucial element of parking lot management is the drainage system. Properly functioning drainage prevents water accumulation, which can damage the surface and create hazards.

Regularly inspect catch basins and pipes for blockages. Clear any debris that hinders water flow. Implementing effective water management strategies helps maintain the integrity of your parking surface.

Consider grading the lot to direct water away from entrances and other high-traffic areas. Efficient drainage protects your investment and provides a safe environment for users.

Guard Rails, Fences, and Handrails

Safety barriers like guard rails, fences, and handrails are essential to protect pedestrians and vehicles. Ensure they are regularly inspected for damage or wear. A damaged barrier can result in serious accidents.

Install guard rails in areas where vehicles could veer off course. Fences should delineate property lines and create secure boundaries. Handrails offer support in elevated or sloped areas, enhancing accessibility.

Trueline Striping understands the importance of clear markings and visible barriers. When it comes to coordinating these features, well-defined traffic lanes improve navigation and safety in your lot.

Additional Considerations for Optimal Maintenance

To ensure long-lasting performance and safety in your parking lot, consider key factors such as environmental impact, security measures, and the management of specialized equipment. These aspects play a significant role in overall upkeep.

Landscape Maintenance and Environmental Impact

Incorporating landscaping not only enhances the aesthetic appeal but also contributes to environmental health. Implementing native plants can minimize water usage while improving air quality. Regular maintenance, including pruning and mulching, fosters a healthy landscape that can support stormwater drainage.

Utilizing environmentally friendly practices such as anti-icing agents in winter conditions can significantly reduce harmful runoff. Additionally, proper waste management and recycling initiatives ensure that your lot remains clean, safeguarding local ecosystems from pollutants.

Parking Lot Security and Emergency Systems

Safety measures in parking lots are crucial. Implementing offsite surveillance cameras can deter criminal activity and provide peace of mind. Emergency panic alarms enable quick communication with authorities, enhancing overall security.

Consider adding tire deflation devices for added safety against unauthorized vehicles. Regular maintenance checks on security systems will ensure they are operational when needed. A secure environment not only protects assets but also ensures customer safety, fostering trust in your business.

Managing Shopping Basket Corrals and Specialized Equipment

Efficient management of shopping basket corrals is essential for customer convenience and safety. Designate clear areas for these corrals to prevent congestion, ensuring they do not obstruct traffic flow.

Routine inspections help prevent damage and keep them easily accessible. Specialized equipment such as snow removal tools or maintenance vehicles should be managed efficiently to maintain smooth operations. Ensure areas are designated for their storage to optimize space and reduce hazards.

For all your parking lot striping needs, Trueline Striping offers services across Waco, Temple, Belton, Killeen, and Central Texas. Your investment in maintenance will translate into a safer, more efficient space for both customers and employees.

Frequently Asked Questions

Maintaining a parking lot is crucial for safety and efficiency. Here are answers to common questions about essential inspections, maintenance checklists, and infrastructure priorities.

What are the essential steps included in a parking lot maintenance walk-through?

During a walk-through, check for surface cracks, potholes, and drainage issues. Evaluate the condition of markings and signage, ensuring they are visible and compliant with regulations. Inspect the lighting for functionality, and note any areas needing immediate attention.

How often should a facility's parking area be inspected?

Inspect your parking area at least twice a year, or more frequently based on traffic volume and weather conditions. Regular inspections help identify issues early, reducing repair costs and enhancing safety for all users.

Which items should be on a checklist for routine parking lot maintenance?

Your checklist should include surface inspections, cleaning debris, checking drainage systems, and reviewing paint markings. Document any damage or necessary repairs to keep track of maintenance activities effectively.

What safety measures need to be reviewed during a parking lot inspection?

Ensure that all pedestrian paths are marked clearly and that any hazards, such as potholes or debris, are addressed promptly. Inspect lighting to confirm adequate visibility for both vehicles and pedestrians during nighttime.

Can you provide a template for documenting parking lot maintenance activities?

Create a simple template that includes the date, specific tasks performed, any issues found, and follow-up actions needed. Include space for signatures and notes from the inspection to keep a clear record of maintenance history.

What specific elements of parking lot infrastructure should be prioritized in a maintenance plan?

Prioritize pavement condition, proper drainage systems, and clear markings for traffic and pedestrian flow. A focus on ADA compliance is crucial to ensure accessibility for all customers.

For professional assistance with your parking lot striping and maintenance, consider Trueline Striping. We offer services across Waco, Temple, Belton, Killeen, and Central Texas. From new construction to restriping and ADA compliance, we ensure your parking lot meets all safety and efficiency standards.

Thermoplastic Striping: A Comprehensive Guide to Durable Road Markings

Thermoplastic striping is a durable marking solution used for road and parking lot applications.

Thermoplastic striping is a superior solution for creating durable and reflective pavement markings that enhance safety and organization in various environments. This material offers longevity and visibility, making it ideal for high-traffic areas such as parking lots, roads, and athletic courts. When properly applied, thermoplastic striping can withstand harsh weather conditions and heavy usage, ensuring that your markings remain clear over time.

At Trueline Striping, we specialize in comprehensive parking lot striping services across Central Texas, including Waco, Temple, Belton, and Killeen. Regardless of whether it’s new construction striping or a restripe of faded lines, we use top-quality materials to provide a professional finish that meets your needs. With thermoplastic striping, you can create designated spaces that promote smooth traffic flow and enhance safety for both customers and employees.

Choosing thermoplastic striping not only improves the aesthetic appeal of your property but also ensures compliance with regulations such as ADA. At Trueline Striping, we are committed to delivering exceptional results, making your space both functional and welcoming. Let us help you elevate your property with our expert striping services tailored to your requirements.

What Is Thermoplastic Striping?

Thermoplastic striping is a durable marking solution used for road and parking lot applications. It stands out for its long-lasting qualities and reflective properties, making it ideal for high-traffic areas. This section will explore how it compares to traditional paint markings and its key components.

Comparison With Traditional Paint Markings

Thermoplastic striping differs significantly from traditional paint markings. While paint is typically water-based and requires frequent maintenance, thermoplastic materials are designed for durability. Thermoplastic becomes pliable when heated, allowing it to adhere effectively to the pavement.

Key benefits of thermoplastic striping include:

Longevity: Thermoplastic can last 5 to 7 years, significantly outlasting standard paint.

Reflectivity: The addition of glass beads enhances visibility at night.

Cost-effectiveness: Reduced need for frequent touch-ups results in lower long-term costs.

In locations like Waco, Temple, Belton, and Killeen, using thermoplastic for parking lot striping ensures safety and clarity, vital for maintaining organized traffic flow.

Key Components of Thermoplastic Material

Thermoplastic striping comprises several essential components that contribute to its effectiveness. The primary ingredients include pigments, binders, and glass beads.

Pigments: These provide the desired color for the markings.

Binders: Binders hold the material together and enhance adhesion to surfaces.

Glass beads: These are embedded within the material to improve reflectivity, making stripes visible in low-light conditions.

Together, these components create a robust and reliable marking solution. Trueline Striping employs high-quality thermoplastic materials to ensure your parking lot not only looks great but is also functional. From new construction striping to ADA compliance, investing in thermoplastic striping is a wise choice for any property.

Benefits and Performance of Thermoplastic Striping

Thermoplastic striping offers numerous advantages that enhance the performance of road and parking lot markings. Its durability, visibility, and environmental considerations make it an excellent choice for various applications. Below are some key benefits that highlight why thermoplastic striping is a preferred option in many areas.

Durability and Longevity

One of the standout features of thermoplastic striping is its exceptional durability. Made from high-quality materials, it resists cracking, chipping, and shattering, even under heavy traffic conditions. This resilience results from the unique bonding process and the inclusion of glass beads, which add strength and stability.

In terms of longevity, thermoplastic striping significantly outlasts traditional paint. While paint may require frequent reapplication, thermoplastic can maintain its clarity and integrity for many years. This extended lifespan ultimately translates to lower maintenance costs, providing excellent value for your investment.

For businesses relying on well-marked spaces, the durability of thermoplastic ensures that your markings remain clear and effective, enhancing both safety and aesthetic appeal.

High Reflectivity and Nighttime Visibility

Visibility is crucial for safety, especially at night or in low-light conditions. Thermoplastic striping incorporates glass beads that enhance reflectivity, ensuring that your lines are highly visible even at night. This feature is particularly important for parking lots and roads where clear markings can prevent accidents.

The reflectivity of thermoplastic contributes to improved nighttime visibility for drivers and pedestrians alike. This means you can effectively manage traffic flow and enhance safety for all users of your space. Well-defined markings reduce confusion and improve navigation, which is essential in busy environments.

Investing in thermoplastic striping means investing in safety and visibility, allowing you to meet the expectations of both customers and regulatory standards.

Environmental Considerations

When choosing materials for striping, environmental impact is an important factor. Thermoplastic striping is formulated with fewer volatile organic compounds (VOCs) compared to traditional paint. This makes it a more environmentally friendly option, contributing to better air quality.

Additionally, its long lifespan reduces the frequency of reapplication, which means less waste and lower resource consumption over time. By opting for thermoplastic striping, you align your business with sustainable practices while ensuring your parking lot remains both functional and eco-friendly.

For effective striping solutions that prioritize durability and environmental considerations, Trueline Striping can help you achieve your goals.

Applications of Thermoplastic Striping

Thermoplastic striping is widely used for various applications, ensuring safety and efficiency in different environments. Understanding the specific applications can help you make informed decisions about your own striping needs.

Road Markings

Thermoplastic striping is a preferred choice for road markings due to its durability and visibility. It withstands heavy traffic and harsh weather conditions, making it suitable for highways and city streets.

The reflective properties of thermoplastic markings enhance nighttime visibility, crucial for driver safety. Applications include lane lines, edge lines, and other critical markings that guide vehicle movement. Detailed planning ensures proper placement and dimensions according to local regulations.

Parking Lot Markings

In parking lots, thermoplastic markings provide clear guidance for both vehicles and pedestrians. Trueline Striping specializes in creating distinct layouts, improving organization and safety for your customers.

New construction striping or restriping services can revitalize your space, ensuring compliance with ADA regulations. The longevity of thermoplastic materials means minimal maintenance, allowing you to focus on your business. Varied applications include parking stalls, loading zones, and directional arrows.

Pedestrian Crossings

Pedestrian crossings play a vital role in enhancing safety in urban areas. Thermoplastic striping creates highly visible crosswalks that alert drivers to the presence of pedestrians.

Usually implemented in high-traffic areas, these markings can be supplemented with additional safety features such as warning signs or flashing lights. Ensuring that your pedestrian crossings meet regulatory standards is crucial for both safety and liability.

Traffic Flow and Control

Effective traffic control is essential for smooth operations in busy environments. Thermoplastic markings can be used to direct traffic flow, thereby reducing congestion and preventing accidents.

Applications for traffic control include stop lines, yield markings, and no-parking zones. By clearly defining these areas, you're setting the stage for safer travel. Properly executed thermoplastic striping helps in maintaining order and enhances the overall safety of your property.

Application Process and Equipment

The application of thermoplastic striping requires careful preparation and the right equipment to ensure durability and visibility. Understanding the surface preparation, heating methods, and specialized equipment involved is essential for achieving optimal results.

Surface Preparation

Before applying thermoplastic material, proper surface preparation is crucial. Ensure the pavement is clean, dry, and free from debris. A scarifier may be used to remove any existing tape, paint, or loose material. This helps the new thermoplastic adhere effectively to the surface.

Additionally, the surface should be inspected for cracks or damages that may require repair before striping. The temperature should also be monitored, as applying thermoplastic in unsuitable conditions could impair its performance. Taking these preparatory steps can significantly improve the longevity of the markings.

Heating and Applying the Material

Heating the thermoplastic material is a critical part of the application process. The material must be heated to a temperature between 400°F to 440°F for proper application. A premelt kettle is typically used for this purpose, ensuring that the material reaches the necessary viscosity.

Once heated, the thermoplastic can be applied using specialized equipment. Timing is important—you must apply the material promptly after heating to avoid cooling and hardening. The application should be uniform to create clear and distinct line markings. Ensuring the right ambient conditions during application will greatly enhance the quality and durability of the striping.

Specialized Application Equipment

Utilizing the right application equipment is key to successful thermoplastic striping. Line stripers designed specifically for thermoplastic applications will ensure a precise and uniform application. These machines can often be adjusted for different line widths based on your project requirements.

At Trueline Striping, we emphasize the use of high-quality, specialized equipment tailored for working with thermoplastic materials. This equipment not only improves efficiency but also guarantees that the markings are consistent and meet your specifications. Whether for new construction striping or restriping, the right tools make a substantial difference in the end result.

Types and Solutions for Thermoplastic Markings

Thermoplastic markings offer various solutions tailored to specific needs. Understanding the types available can help you make informed decisions for your projects. The following subsections detail the options you have in terms of preformed thermoplastic and custom striping solutions.

Preformed Thermoplastic Options

Preformed thermoplastic options are ideal for quick application and consistent results. These markings come in pre-cut shapes and can be easily installed onto clean, dry surfaces.

Advantages include:

Time Efficiency: Saves labor time as they can be applied without extensive preparation.

Durability: Offers long-lasting performance, even in high-traffic areas.

Flexibility: Suitable for intricate designs required for different applications.

You can find preformed options for crosswalks, arrows, and symbols, ensuring high visibility. Many contractors prefer these for their reliability and ease of use, making them a popular choice in parking lots and roadways. At Trueline Striping, we can assist you in selecting the right preformed thermoplastic solutions for your needs.

Custom Striping Solutions

Custom striping solutions allow you to design markings that suit your specific requirements, whether for new construction or restriping. Tailored to your vision, these solutions utilize thermoplastic materials that enhance longevity and visibility.

With custom options, you can specify:

Colors: Different colors for various sections like designated parking or traffic flow.

Patterns: Unique patterns for athletic courts or special event spaces.

ADA Compliance: Proper markings to accommodate individuals with disabilities.

This flexibility ensures that your markings align with both safety regulations and aesthetic preferences. At Trueline Striping, we provide expert guidance to help you create effective, compliant designs for your project in Central Texas.

Frequently Asked Questions

This section addresses common inquiries related to thermoplastic striping, including its advantages and disadvantages, cost considerations, and longevity compared to traditional paint. Understanding these aspects can help you make informed decisions for your striping needs.

What are the benefits and drawbacks of using thermoplastic for road striping?

Thermoplastic offers significant durability and is highly visible, making it ideal for high-traffic areas. It dries quickly and can withstand harsher weather better than traditional paint.

However, installation costs are higher, and the material may require specialized equipment. You should consider these factors based on your specific requirements.

How does thermoplastic striping compare to traditional road paint in terms of longevity and cost?

Thermoplastic typically lasts longer than standard road paint, often exceeding three to five years under normal conditions. While the initial investment is higher, the extended lifespan can provide better long-term value.

Traditional paint may be less expensive upfront but often requires more frequent reapplication in busy areas, which can increase overall costs.

What is the typical lifespan of thermoplastic striping under normal traffic conditions?

Under normal traffic conditions, thermoplastic striping can last anywhere from three to seven years. Factors like traffic volume and environmental conditions play a role in its longevity.

For optimal performance, regular inspections and maintenance are recommended to address any wear and tear.

Can existing thermoplastic striping be overlaid with paint, and if so, how does it affect durability?

Yes, you can overlay existing thermoplastic striping with paint. However, this can affect durability, as paint may wear off more quickly than thermoplastic.

It's important to ensure that the surface is properly prepared and the materials are compatible to maximize the effectiveness of the paint.

How is the cost of thermoplastic striping determined, and what factors influence its price per linear foot?

The cost of thermoplastic striping is influenced by several factors, including the type of project, the complexity of the layout, and the density of the material used.

Additionally, local labor costs and specific site conditions can impact the overall pricing per linear foot.

What equipment is required for the application of thermoplastic striping, and is it available for rent?

Applying thermoplastic striping requires specialized equipment such as a thermoplastic extruder or pre-melter. These machines heat and dispense the thermoplastic material onto the pavement.

You can often find this equipment available for rent, making it accessible for various project needs. For efficient results, consider partnering with a professional service like Trueline Striping.

How to Layout Parking Lot Lines: A Step-by-Step Guide for Optimal Space Management

Effective parking lot layout involves several key considerations that can enhance both functionality and safety.

Creating a well-organized parking lot layout is crucial for both safety and efficiency. Properly laid out parking lot lines help guide vehicles, improve traffic flow, and enhance the overall aesthetic of your property. Whether you're managing a parking lot for a business or overseeing a new construction, knowing how to effectively stripe your parking lot is essential.

At Trueline Striping, we specialize in transforming spaces with our expert striping services across Central Texas, including Waco, Temple, Belton, and Killeen. We understand the importance of clear markings in ensuring a welcoming environment for your customers and employees. With our commitment to quality and customer satisfaction, you can trust that your parking lot will not only look good but also function efficiently.

In this article, you will learn key steps and best practices for laying out parking lot lines, from selecting the right materials to ensuring compliance with regulations. By the end, you will be equipped with the knowledge to create a safe and organized parking experience that meets your needs.

Planning Your Parking Lot Layout

Effective parking lot layout involves several key considerations that can enhance both functionality and safety. Focused planning will ensure that your lot meets the unique needs of your space while complying with relevant guidelines.

Assessing Lot Size and Measurements

Begin by evaluating the dimensions of your property. Accurate measurements are crucial for a successful design. Identify the total area available and confirm the boundaries before you start planning.

Consider the size of standard parking spaces, typically 9 feet wide by 18 feet long. This allows for comfortable parking and easy vehicle maneuvering. You should also account for additional space for access aisles, which usually require at least 24 feet.

Using this information, create a scaled drawing of your lot layout to visualize the spacing. This will help you determine the number of parking spots while maintaining proper circulation throughout the area.

Determining Traffic Flow and Efficiency

Next, analyze how vehicles will move through your parking lot. Efficient traffic flow is vital for reducing congestion and enhancing safety. Identify entry and exit points, ensuring they are clearly marked and accessible.

Incorporate one-way traffic patterns when possible. This minimizes conflicting movements, making it easier for drivers to navigate the lot. Use directional arrows in your striping to guide vehicle movement.

Planning for efficiency also means considering peak times when traffic may increase. Your design should facilitate smooth circulation even during busy periods. By prioritizing traffic flow, you enhance user experience and promote safety.

Choosing Parking Angle Types

Selecting the appropriate parking angles is essential for maximizing space and ensuring ease of access. Common angles include 90-degree, 60-degree, and 45-degree configurations.

90-degree parking offers the most efficient use of space but requires more maneuvering room.

60-degree parking balances efficiency and ease of access, making it suitable for many commercial lots.

45-degree parking is ideal for smaller areas, allowing greater visibility and easier entry and exit.

Consider your specific needs and layout constraints when choosing parking angles. Trueline Striping can help ensure your angles are well-defined and clearly marked.

Designing for Accessibility and ADA Compliance

Prioritize accessibility in your layout to meet ADA guidelines. Designate specific accessible parking spots that are wider—generally at least 8 feet—and located nearest to building entrances.

Each accessible space must include proper signage and be marked with clear, bold striping that meets ADA standards. This visibility helps ensure that all customers can find and utilize these spaces easily.

Incorporate accessible routes from parking spaces to building entrances. These should be free of obstacles and include features such as curb cuts. Ensuring compliance not only meets legal standards but also demonstrates a commitment to inclusivity.

Marking Parking Spaces and Aisles

Properly marking parking spaces and aisles is crucial for ensuring a smooth flow of traffic and maximizing the utility of your parking area. Focus on dimensions, layout, and configuration to create an organized and efficient parking environment.

Defining Parking Space Dimensions

Parking space dimensions must comply with local regulations and standards. A standard parking space typically measures 9 feet wide by 18 feet long, accommodating most vehicles. Accessible parking spaces are usually wider, measuring 11 feet to provide room for wheelchair access.

When designing your layout, consider different parking angles:

Perpendicular parking requires more width but maximizes space use.

Angled parking offers easier access and typically requires about 10 to 12 feet in width.

You can consult the ADA Compliance Guide when marking accessible stalls. Ensuring compliance not only helps meet legal requirements but also enhances your facility's inclusivity.

Laying Out Parking Stalls

To lay out parking stalls effectively, start by determining the total area available and the desired parking angle. Establish a grid on paper or with marking chalk to visualize space utilization.

Create a clear layout that considers traffic flow and accessibility. Use distinct lines to separate stalls, ensuring they are at least 4 inches wide for visibility. Marking lines in durable thermoplastic paint is recommended for longevity.

Include necessary indicators such as stall numbers and directional arrows to guide drivers. Trueline Striping emphasizes that a well-structured layout not only maximizes space but also elevates the overall aesthetic of your parking lot.

Configuring Aisle Widths

Aisle widths are critical for maneuverability. For angled parking, a width of 15 to 20 feet is typically sufficient, while perpendicular parking requires wider aisles of at least 24 feet.

These widths ensure vehicles can safely navigate the lot while reducing the risk of collisions. Clearly marked aisles help in directing traffic flow and preventing confusion.

Incorporate signage for clearer communication, especially near entrances and exits. A thoughtful configuration will boost efficiency and improve user experience, critical for facilities in Waco, Temple, Belton, and Killeen. Proper marking creates a welcoming environment, ensuring customer safety and satisfaction.

Executing Parking Lot Striping

Proper execution of parking lot striping involves thorough preparation, the right materials, and effective application techniques. Ensuring compliance with standards and achieving good visibility is critical for safety and functionality.

Surface Preparation Techniques

Before applying any paint, take time for surface preparation. Begin with a thorough cleaning to remove debris, oil, and grime using a pressure washer. This step helps ensure proper adhesion of the paint.

Next, inspect the pavement for cracks or damage. Address any repairs needed by filling cracks with appropriate filler material to create a smooth surface. If the pavement is particularly porous, consider applying a primer to enhance paint adherence.

Weather conditions also play a role. Ensure temperatures are suitable for painting; most water-based paints perform best between 50°F and 90°F. Allow for adequate drying time, especially after rain to avoid peeling.

Selecting Paint Types and Tools

Choosing the right paint is essential for durability and visibility. Common options include water-based and oil-based paints. Water-based paint dries faster and is more environmentally friendly, making it suitable for most parking lot applications. Oil-based paint, while slower to dry, offers excellent durability and is often used on high-traffic areas.

When it comes to tools, a striping machine is vital for achieving crisp, straight lines. Various models are available, ranging from manual options to more advanced, automated machines. Consider reflective paint for increased visibility at night. It’s particularly important for complying with parking lot striping standards.

Applying Effective Striping Patterns

For effective striping, start by marking guidelines using chalk or a string line. This provides a visual reference that keeps your lines straight and evenly spaced. Ensure you adhere to local regulations regarding parking space dimensions.

Begin painting by outlining your designated areas, allowing the paint to flow evenly. Maintain a steady speed while operating the striping machine to avoid thick spots or drips. Multiple coats may be necessary for enhanced visibility.

After striping, remember to allow adequate drying time before opening the lot to traffic. Incorporating these practices will result in a well-executed parking lot striping project that enhances both safety and aesthetics. For professional assistance, consider Trueline Striping, which specializes in parking lot striping throughout Central Texas.

Enhancing Safety and Accessibility Features

A well-designed parking lot layout prioritizes both safety and accessibility. Key features like crosswalks, pedestrian pathways, directional arrows, and stop bars are essential for guiding traffic and ensuring a secure environment for all users.

Incorporating Crosswalks and Pedestrian Pathways

Crosswalks are vital for ensuring pedestrian safety in your parking lot. They should be clearly marked and ideally located near building entrances to facilitate safe access. Incorporating tactile indicators can further assist visually impaired individuals.

Use bold and contrasting colors for crosswalks to enhance visibility. Ensure that pathways are wide enough to accommodate foot traffic without obstruction. Regular maintenance is essential to keep these markings visible and effective.

Consider adding raised crosswalks to slow vehicle speeds and draw attention to pedestrian areas. This feature not only promotes safety but also encourages drivers to remain vigilant. If you're in need of professional assistance, Trueline Striping can help you implement these features effectively.

Directional Arrows and Stop Bars

Directional arrows play a crucial role in guiding vehicle traffic and ensuring smooth flow. These markings should be strategically placed to inform drivers of the intended direction, minimizing confusion and potential accidents.

Stop bars are equally important, clearly indicating where vehicles must halt. Position stop bars at intersections and crosswalks to enhance safety and allow for better visibility of pedestrians. Using high-contrast materials for these markings will optimize their effectiveness.

Regular inspections and maintenance of these features help ensure they remain visible over time. Trueline Striping specializes in enhancing safety through precise marking, ensuring your parking lot complies with necessary regulations while providing a safe experience for everyone.

Future-Proofing And Maintaining Your Parking Lot

Proper maintenance and strategic future-proofing are essential for sustaining the functionality and appeal of your parking lot. Keeping your lines clear and compliant not only enhances safety but also boosts your establishment's image and profitability.

Maintaining and Re-Striping

Regular maintenance and re-striping are fundamental to a well-functioning parking lot. Faded lines can lead to confusion and accidents, which is why timely re-striping is crucial. Signs of wear can include chipped paint and unclear markings.

Scheduling re-striping every 1-2 years can ensure visibility and organization. Use high-quality, durable materials to withstand weather conditions. Trueline Striping offers expert restriping services in locations such as Waco, Temple, and Belton, helping you maintain safe and clear parking spaces.

Sealcoating and Finishing Touches

Sealcoating protects the asphalt from damage caused by UV rays, oil spills, and water. This not only extends the life of your parking lot but also provides an attractive, uniform appearance. It is advisable to sealcoat every 2-3 years.

After sealcoating, apply finishing touches like edge lines and directional arrows. These small details can improve traffic flow. Proper maintenance can lead to increased customer satisfaction and retention, ultimately enhancing your parking lot’s reputation.

Evaluating Parking Revenue and ROI

Monitoring your parking revenue can help you measure the success of your lot's layout and maintenance. Using a parking revenue calculator can offer insights into potential ROI, making it easier to justify maintenance expenses.

Investing in a quality parking system might involve initial costs, but the long-term benefits including improved customer experience and increased revenue can outweigh them. A well-maintained parking lot demonstrates a commitment to safety and efficiency, encouraging repeat business and boosting profits.

Optimizing with Technology and Software

In today’s landscape, technology plays a pivotal role in effectively designing and managing parking lots. Utilizing advanced software and systems can streamline the layout process, leading to improved efficiency and compliance.

Utilizing Parking Lot Design Software

Adopting dedicated parking lot design software significantly enhances your planning process. Tools like ConceptDraw and RoomSketcher allow you to create precise designs tailored to your space. These applications often come with features that let you input dimensions, ensuring accurate layouts.

ParkCAD from Transoft Solutions is another powerful software that provides robust optimization tools. It simplifies the layout process, helping you comply with local regulations while maximizing space efficiency. With these technologies, you can visualize your design, adjusting elements easily as needed.

Implementing Parking Systems

Integrating advanced parking systems can further elevate your parking lot's functionality. Smart parking solutions help manage the flow of vehicles and optimize space utilization. This technology often includes sensors and apps that guide drivers to available spots, reducing waiting times.

These systems can also provide crucial data analytics, helping you understand usage patterns. A well-optimized parking system enhances customer experience while maximizing revenue potential.

Case Study: Software Solutions

Many businesses have successfully transformed their parking layouts using technology. For instance, a retail store utilized Transoft's ParkCAD to restructure its parking lot. The process involved detailed planning based on customer traffic and accessibility requirements.

As a result, the store saw increased customer satisfaction due to improved traffic flow and a more organized parking area. In Central Texas, companies like Trueline Striping leverage these software solutions for efficient striping and compliance, ensuring safety and usability in every project.

By harnessing the power of parking lot design software and smart parking systems, you can create a well-organized, efficient environment for your customers and employees alike.

Frequently Asked Questions

When it comes to laying out parking lot lines, certain standards and techniques are essential for efficiency and safety. The following questions address common concerns related to parking lot striping, including legal requirements, painting methods, and best practices.

What standards must be met for parking lot striping?

Parking lot striping must comply with local regulations and safety standards. This includes ensuring proper spacing, size, and visibility of markings. ADA compliance is also crucial, requiring certain dimensions and signage for accessibility.

Can parking lot lines be painted manually without specialized equipment?

Yes, parking lot lines can be painted manually, but the results may be less precise. Using specialized equipment, such as striping machines, enhances accuracy and consistency, ensuring straight lines and even coverage.

What are the standard dimensions for parking lot lines?

Standard dimensions for parking lot lines typically include 4-6 inches in width for regular spaces. The length is generally determined by the space size, with typical parking spaces measuring 9-10 feet wide and 18-20 feet long.

What techniques are used for striping a parking lot efficiently?

Efficient striping techniques include using laser alignment systems and digital layout planning software. These tools help achieve precision in line placement and measurement, reducing the risk of errors that can occur with manual methods.

How are parking spaces calculated in a new parking lot layout?

When calculating parking spaces, you need to consider the total area and the dimensions of each space. Factor in required aisles for vehicle access, ensuring adequate space for maneuvering, and adhere to local zoning regulations for parking density.

What guidelines should be considered in designing a functional parking lot layout?

Key guidelines for a functional parking lot layout include ensuring smooth traffic flow, proper signage, and compliance with safety regulations. Consider factors such as entry and exit points, accessible spaces, and pedestrian pathways for optimal functionality.

For professional parking lot striping services, consider Trueline Striping, which operates in Waco, Temple, Belton, Killeen, and Central Texas. They offer a range of services from new construction striping to ADA compliance solutions.